National fuel gas code ansi z223 1 – The National Fuel Gas Code ANSI Z223.1 serves as the cornerstone for safe and efficient gas distribution and utilization practices. This comprehensive code establishes industry-wide standards and guidelines to minimize hazards associated with natural gas systems, ensuring the well-being of communities and the protection of property.

The NFGC has evolved over decades, reflecting advancements in technology and best practices. Its provisions cover a wide range of aspects, including gas piping systems, appliances, equipment, installation, maintenance, and safety considerations.

National Fuel Gas Code Overview

The National Fuel Gas Code (NFGC) is a comprehensive set of regulations governing the installation and use of fuel gas systems in the United States. It is developed by the National Fire Protection Association (NFPA) and serves as a benchmark for ensuring the safety and efficiency of fuel gas systems in residential, commercial, and industrial settings.

The NFGC covers a wide range of topics related to fuel gas systems, including the design, installation, operation, and maintenance of gas piping, appliances, and equipment. It provides detailed requirements for materials, construction methods, and safety measures to minimize the risks associated with fuel gas use.

Scope and Applicability

The NFGC applies to all fuel gas systems, regardless of the type of gas used (natural gas, propane, etc.) or the size of the system. It is mandatory in many jurisdictions throughout the United States and serves as a model code for others.

History and Evolution

The NFGC was first published in 1927 as the “American Standard Code for the Installation of Gas Piping and Gas Appliances.” Over the years, it has undergone numerous revisions and updates to reflect changes in technology, safety standards, and industry best practices.

The current edition of the NFGC is NFGC 2021.

Key Provisions of the NFGC

The NFGC is a comprehensive document that covers all aspects of gas piping systems, appliances, and equipment. It is divided into six main sections:

- Section 1: General Provisions

- Section 2: Piping Systems

- Section 3: Appliances

- Section 4: Equipment

- Section 5: Venting Systems

- Section 6: Referenced Standards

Each section is further divided into chapters that cover specific topics. For example, Section 2 on Piping Systems includes chapters on materials, installation, and testing.The NFGC contains a number of specific requirements related to gas piping systems, appliances, and equipment.

These requirements are designed to ensure the safe and efficient operation of gas systems. Some of the most important requirements include:

- Gas piping systems must be designed and installed in accordance with the NFGC.

- Appliances must be installed and maintained in accordance with the manufacturer’s instructions.

- Equipment must be installed and maintained in accordance with the NFGC.

The NFGC also contains a number of safety regulations and standards. These regulations and standards are designed to protect the public from the hazards of gas. Some of the most important safety regulations include:

- Gas piping systems must be inspected and tested regularly.

- Appliances must be inspected and serviced regularly.

- Equipment must be inspected and maintained regularly.

The NFGC is an essential resource for anyone who works with gas piping systems, appliances, or equipment. It is a valuable tool for ensuring the safe and efficient operation of gas systems.

Installation and Maintenance Guidelines

Ensuring the safety and reliability of gas piping systems requires adherence to specific installation and maintenance guidelines. These guidelines encompass proper ventilation, clearances, testing procedures, and regular inspections to minimize potential hazards and ensure optimal performance.

Ventilation

Adequate ventilation is crucial for the safe operation of gas piping systems. Proper ventilation allows for the dissipation of any gas leaks, preventing the accumulation of explosive or toxic concentrations. The NFGC specifies the minimum ventilation requirements for different types of gas appliances and spaces.

- Natural ventilation: Utilizing windows, doors, or other openings to allow for air exchange.

- Mechanical ventilation: Employing fans or other mechanical devices to ensure proper airflow.

Clearances

Maintaining appropriate clearances around gas piping systems is essential to prevent fire hazards and facilitate maintenance. The NFGC provides specific clearance requirements for different types of gas piping and appliances, including clearances from combustible materials, walls, and other equipment.

Testing Procedures

Thorough testing procedures are essential to ensure the integrity and safety of gas piping systems. The NFGC Artikels various testing methods, including:

- Leak testing: Verifying the absence of leaks in gas piping and connections using specialized equipment.

- Pressure testing: Assessing the ability of the piping system to withstand specified pressure levels.

- Combustion testing: Evaluating the proper operation and efficiency of gas appliances.

Regular Inspections and Maintenance

Regular inspections and maintenance are vital for the long-term safety and reliability of gas piping systems. These inspections should be conducted by qualified personnel and involve:

- Visual inspections: Examining the piping system for any signs of damage, corrosion, or leaks.

- Operational checks: Ensuring that gas appliances are functioning properly and safely.

- Cleaning and adjustments: Removing debris, dirt, or other obstructions that may affect the performance of the system.

By following these installation and maintenance guidelines, homeowners, businesses, and gas professionals can help ensure the safe and efficient operation of gas piping systems, minimizing the risk of accidents and maximizing the benefits of natural gas.

Safety Considerations: National Fuel Gas Code Ansi Z223 1

Natural gas systems can pose significant safety hazards if not properly installed, maintained, and operated. These hazards include:

- Explosions:Natural gas is a highly flammable gas that can explode when mixed with air in the right proportions. Explosions can cause severe damage to property and infrastructure and can result in injuries or death.

- Fires:Natural gas fires can be extremely dangerous, especially if they occur in enclosed spaces. Fires can cause burns, smoke inhalation, and structural damage.

- Asphyxiation:Natural gas can displace oxygen in enclosed spaces, leading to asphyxiation. Asphyxiation can be fatal if not treated promptly.

Leak Detection

It is important to be able to detect natural gas leaks promptly to prevent accidents. There are a number of ways to detect leaks, including:

- Smell:Natural gas has a distinctive odor that can be detected by humans. However, it is important to note that the odorant can fade over time, so it is not always reliable.

- Sound:Gas leaks can sometimes be detected by the sound of escaping gas. This sound can be a hissing or whistling noise.

- Bubbles:Gas leaks can also be detected by the formation of bubbles in water. This can be done by placing a soapy solution over suspected leak areas.

Emergency Response

If you suspect a natural gas leak, it is important to take the following steps:

- Evacuate the area immediately.

- Call 911.

- Do not smoke or use open flames.

- Ventilate the area.

Accident Prevention

There are a number of steps that can be taken to prevent natural gas accidents, including:

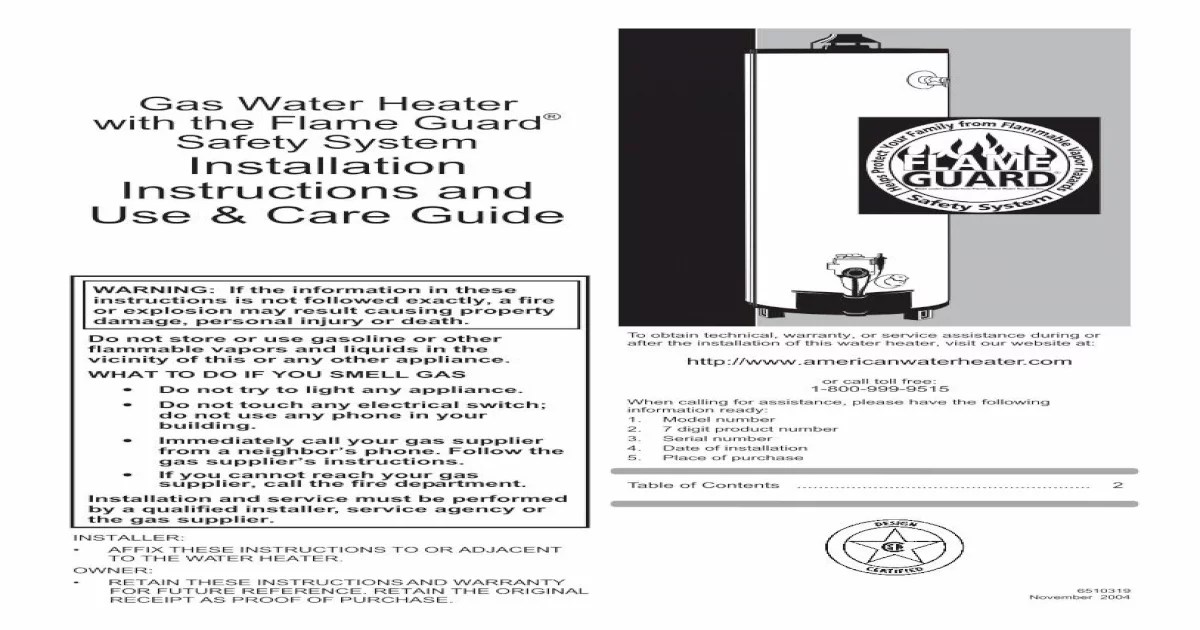

- Proper installation:Natural gas systems should be installed by qualified professionals.

- Regular maintenance:Natural gas systems should be inspected and maintained regularly by qualified professionals.

- Leak detection:Natural gas leaks should be detected promptly and repaired.

- Training and certification:Personnel who work with natural gas systems should be trained and certified.

Role of Training and Certification

Training and certification are essential for enhancing safety in the natural gas industry. Training can help personnel to identify and mitigate hazards, while certification ensures that personnel have the necessary skills and knowledge to work with natural gas systems safely.

Industry Applications

The NFGC plays a vital role in ensuring safety across a wide range of industries and applications where gas-fueled systems are utilized.

From residential homes to large-scale industrial facilities, the NFGC provides comprehensive guidelines to minimize risks associated with the design, installation, and maintenance of gas systems.

Residential Applications

- Single-family homes and apartments

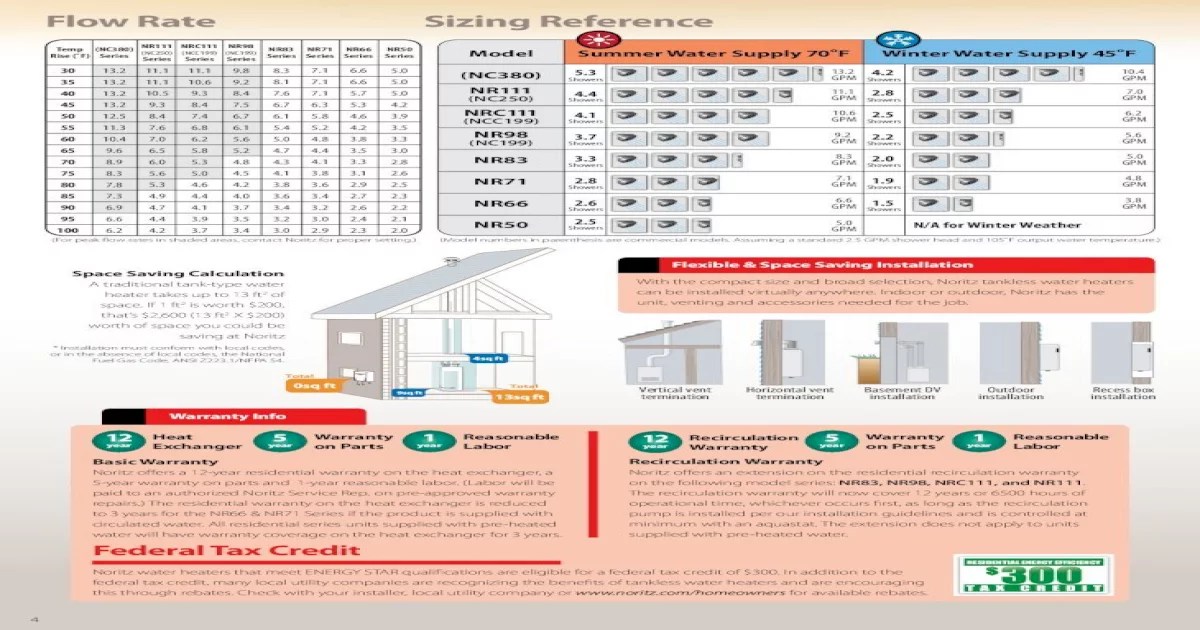

- Gas appliances such as stoves, furnaces, and water heaters

- Ensures proper ventilation, gas line sizing, and appliance installation

Commercial Applications

- Restaurants, hotels, and hospitals

- Commercial kitchens, laundry facilities, and heating systems

- Addresses specific safety concerns related to high-volume gas usage and complex systems

Industrial Applications, National fuel gas code ansi z223 1

- Manufacturing plants, warehouses, and power generation facilities

- Industrial furnaces, boilers, and gas turbines

- Emphasizes safety measures for large-scale gas systems, hazardous materials handling, and emergency response plans

Question Bank

What is the purpose of the National Fuel Gas Code ANSI Z223.1?

The NFGC establishes minimum safety requirements for the design, installation, and maintenance of gas piping systems, appliances, and equipment to prevent hazards associated with natural gas.

Who is responsible for enforcing the NFGC?

Enforcement of the NFGC typically falls under the jurisdiction of local authorities, such as building inspectors or fire marshals.

What are the key provisions of the NFGC?

The NFGC covers a wide range of provisions, including requirements for gas piping materials and installation, appliance safety, ventilation, and emergency response procedures.